Electric Vehicle Series (Part 6)

In my last article, we explored current solutions to car battery pollution, but now it’s time to take the topic a little further. Exploring electric battery development and manufacturing companies, can give great insight on how technology is progressing to create better batteries. This article will be a first-hand inside glance at what really happens in these manufacturing industries. So make way for new ideas and better performance tactics coming straight from the heart of it all!

We’re going to start with one of the biggest vehicle companies in the world, the all-electric car brand, Tesla. Founded July 1st, 2003, this company was based in California, which brings up the first point of EV design. An important factor to consider when making a car is the weather conditions it will have to function in. In California, it’s hot all year long and it doesn’t snow. It has been mentioned that Tesla only takes into account the hot weather of California, making it less ideal in cold climates. Batteries need heat in order to function properly, and heating up a car requires the use of the battery’s energy. Heating the air inside the car and warming the seats also require battery energy. Along with that, the cold air creates drag, working as a dynamic load on the car. This results in a lot less energy for the car to move, and a much lower range capacity, making it more likely for you to be trapped in the middle of the road in the middle of a blizzard.

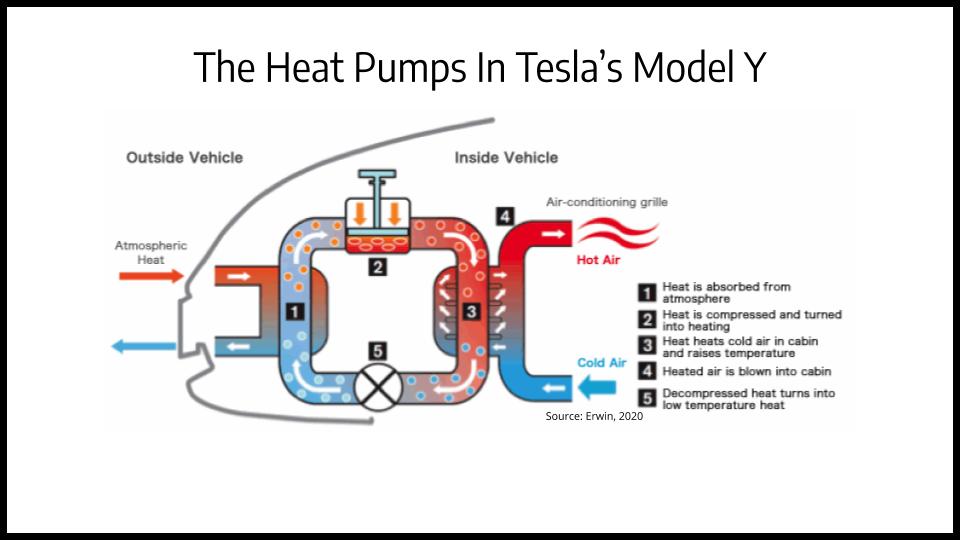

Of course, Tesla’s electric cars have heat-pumps, but that doesn’t solve the problem. Heat-pumps can only move heat around, they can’t produce any energy. Plus, there’s not really any point to them since they stop working at a certain temperature, and the weight and complexity of them makes them extremely expensive. It’s simply not ideal, for functional use, or your wallet. So how did Tesla solve this problem?

Well, with a little tweaking and hard work, in Tesla’s model Y, they have adjusted the pump so that it can start working in -20oC temperatures and so that they now direct heat towards the comfort of the occupants of the car and the car battery, which allows the vehicle to keep running. As seen in the diagram, these new models work like air conditioning, except with a valve that allows it to work in the opposite way. It extracts whatever traces of heat that can be found on the outside of the car, and pushes it into the car. Now that’s a problem solved.

Another thing that Tesla is bringing into the market with it’s new models are improved lithium ion batteries. They are moving on from lithium-ion batteries with 250 wh/kg (watt hours per kilogram) to lithium ion batteries with 300 wh/kg. This means that these batteries will last longer than their prior sets.

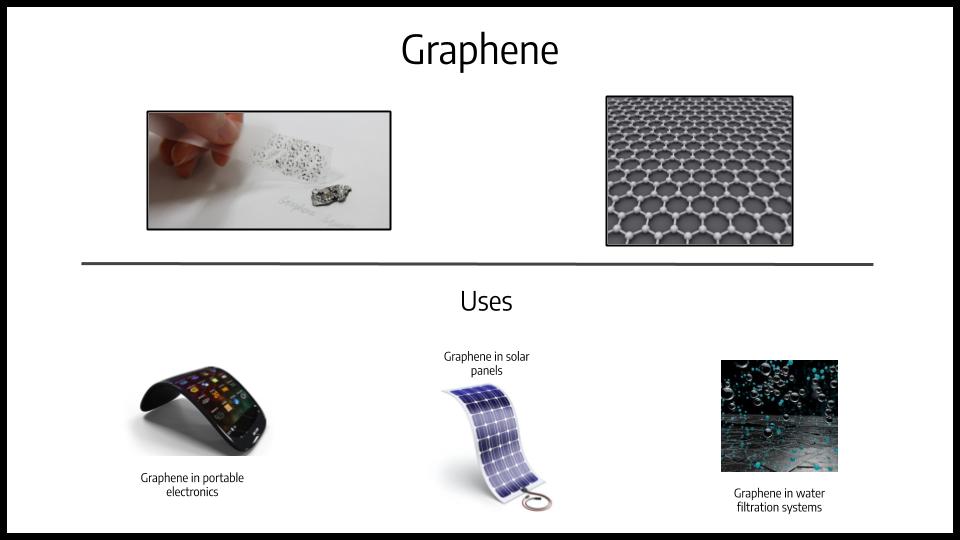

After exploring Tesla, it’s time to take a look at other EV companies. Namely, another extremely famous one, Samsung, founded May 1st, 1938. Samsung is on the verge of new battery technology, creating a graphene battery which should be able to charge 5 times faster than lithium ion batteries. But first, what is graphene?

Well, this revolutionary technology was discovered by Andre Geim and Konstaintin Novoselov, for which they won the Nobel Prize in Physics, 2010. In simple terms, it’s an extremely thin layer of graphite. It was discovered by accident: when using scotch tape to polish graphite, tiny specs were observed on the tape. As they continued to peel the scotch tape against the graphite, graphene was formed. Taking a look at its chemical structure, you can see that it shares the same atoms as carbon, just arranged in a different way, making it an allotrope. Another allotrope of carbon and graphene is diamond, the hardest substance on earth. The atoms in graphene are shaped in a hexagonal pattern and are only 1 atom thick, making it the first truly 2D item ever discovered by mankind. Even more, it’s the strongest material in the known universe. This substance is a semiconductor and can be used in portable electronics, solar panels and water filtration.

Graphene is a miracle substance, the technology of the future. It’s thinner than paper, yet stronger than steel, and impenetrable by most solids and liquids. Using these as EV batteries could open up the industry to endless more possibilities. But right now, all we can do is wait for the first EV to be introduced with this odd, peculiar material.

Now, in the EV industry, companies don’t only develop new battery technology, but they find different and innovative ways to reuse them. Other than being used for solar panels or electric grids, famous companies world wide have found other places to put the used car batteries to further use. Let’s take a look at some of them:

-In Japan, Nissan has used such batteries to provide power to streetlights, and in Paris, Renault has used the batteries to power elevators. That’s some thinking out of the blue!

-General Motors used Chevy Volt Batteries for personal use – as their research base in Michigan!

-Last but not least, private companies such as Powervault from the UK and Aceleron from Australia turn such electric batteries into power for electricity storage units in homes, and electric bikes. Way to reuse!

Looking into EV companies has been insightful, and allows for a more in depth understanding of what happens in regards to EV batteries and how minds can work ingeniously to solve energy problems. For my next and final article, I’m going to be looking at things on a larger scale – a global scale. Stay tuned to figure out what’s next for these electric vehicles and their batteries!